KFS Framemaker Roll Forming Machines

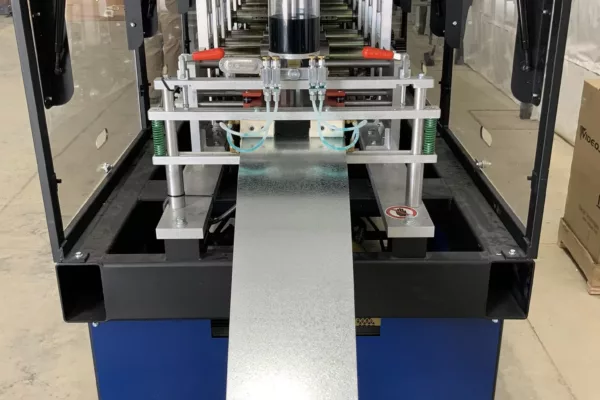

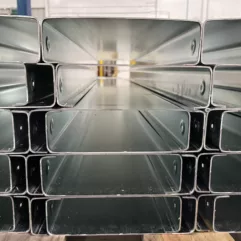

Ideal roll forming equipment for stud and track suppliers, off-site construction, commercial and residential steel framing fabricators, modular contractors, and panelized construction. Optimized for structural load-bearing applications.

HIGHLIGHTS

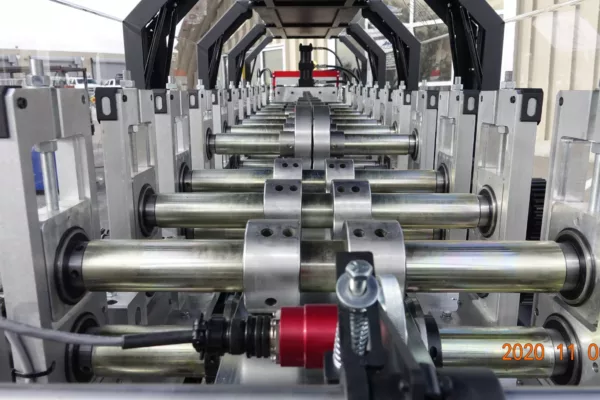

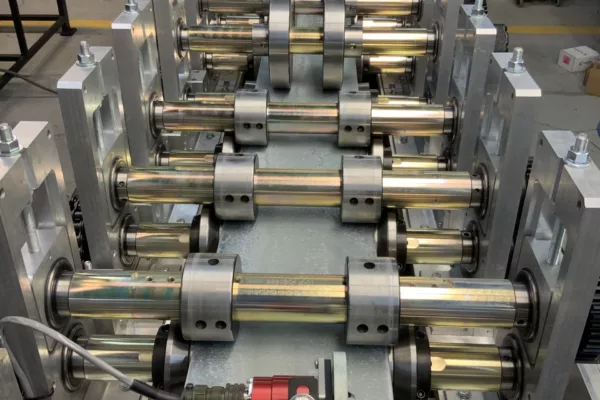

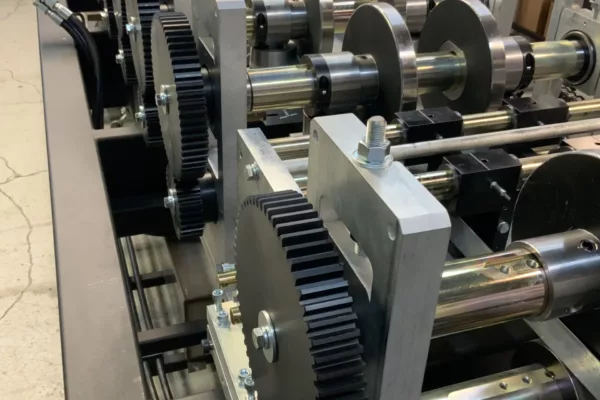

Better Performance

Proven reliable performance and the speed of up to 7,200 ft/hour (2,200 m/hr) with a servo (electric) drive and the ability to process steel coil with yield strength of 65 ksi (450 MPa) & tensile strength of 75 ksi (520 MPa).

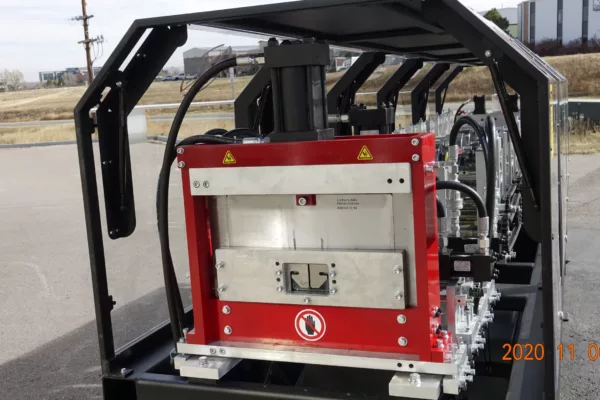

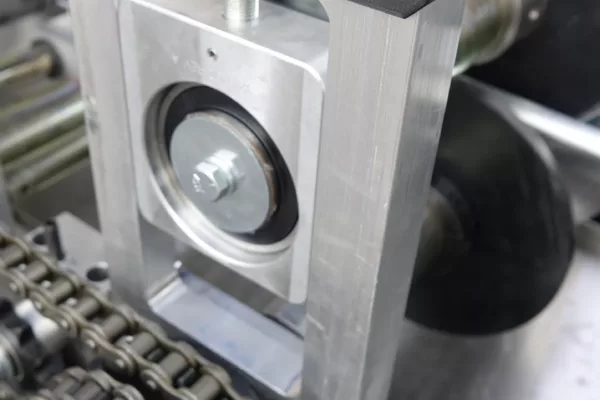

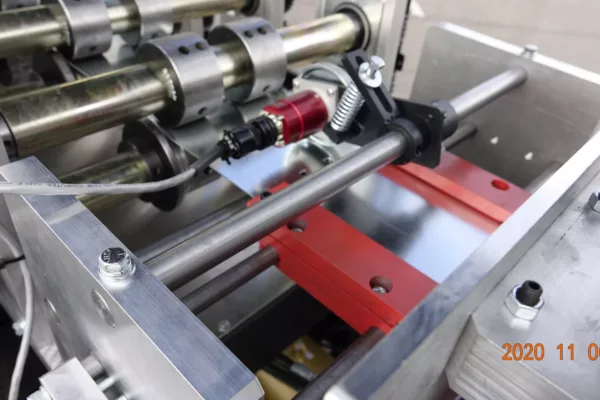

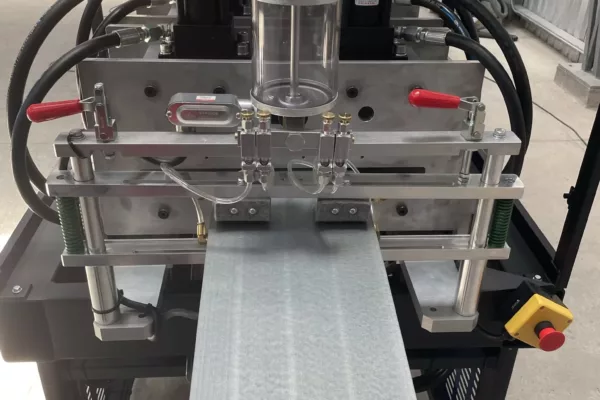

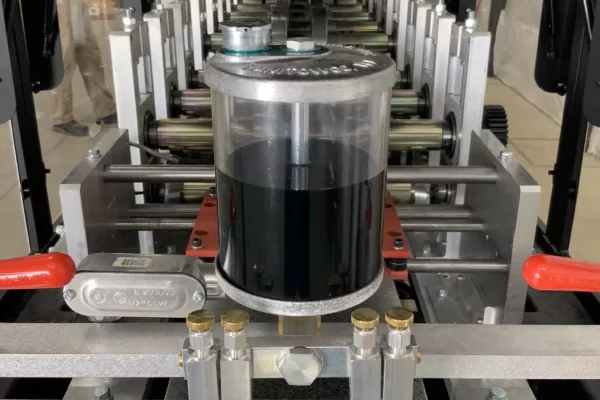

Expert Precision

Equipped with Hydraulic cut-off and punch tools for precise operations. And a Servo (electric) drive system for high precision.

Better Efficiency

With an integrated digital batch controller, you get a more efficient process management. The heavy gauge structural stud and track forming machine forms six (6) web widths and three (3) flange heights in 14 to 20 Ga steel.

AUTOMATION

Supports automated feeding, cutting, and punching for increased productivity.

Compatibility Standards

Meets ASTM A1008 and ASTM 653 standards for Grade 33 structural steel.

Multi-Software Compatibility

Knudson framing machine controllers are compatible with Strucsoft MWF, ScotSteel, Framebuilder MRD, and Vertex.

KFS FRAMEMAKER MODELS

Features

Brochures & Resources

KFS Framemaker 1218G1

- 460V – 60Hz – 3 Phase

- 380V – 50Hz – 3 Phase

- Standard powertrain

- Standard multi-profile Shear Blade/Die Kits

- Beck Automation SII control system with color touch-screen display

- Fast rolling cage adjustment for shifting between profile sizes

- 6500-lb (2,950-kg) powered decoiler with automated coil feed speed control

- Flange dimpling punch toolkit

- Web service hole punch toolkit (1.50 x 3.00 in., 38 x 76 mm)

- Thickness range: Ga. 18 – Ga. 12 (1.1 mm – 2.7 mm)

- Multi Profile: Web 6.00, 8.00, 10.00, 12.00 in.

- Multi Profile Flange: 2.00, 2.50, 3.00, 3.50 in.

- Max return: 0.75 in. (19 mm)

- SFIA/SSMA standard profiles

KFS Framemaker 1218G2

- 460V – 60Hz – 3 Phase

- 380V – 50Hz – 3 Phase

- Standard Power Train

- Profile-Specific Sized Shear Blade/Die Kits

- AMS control system with ScotRF interoperability

- Fast rolling cage adjustment for shifting between profile sizes

- 6,500-lb (2,950-kg) powered decoiler with automated coil feed speed control

- Flange dimpling punch toolkit

- Web service hole punch toolkit (1.50 x 3.00 in., 38 x 76 mm)

- Large service hole web punch toolkit

- Web shear tab connection punch toolkit

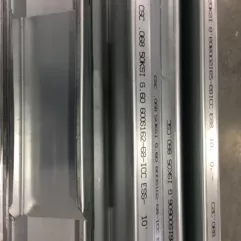

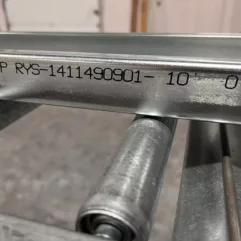

- Inkjet Labeling Printer

- Spare parts kit (2-year supply)

- Thickness range: Ga. 18 – Ga. 12 (1.1 mm – 2.7 mm)

- Multi Profile: Web 6.00, 8.00, 10.00, 12.00 in.

- Multi Profile Flange: 2.00, 2.50, 3.00, 3.50 in.

- Max return: 0.75 in. (19 mm)

- SFIA/SSMA standard profiles

Features

Brochures & Resources

KFS Framemaker 1420 Brochures & Resources

KFS Framemaker 1420G1

- 460V – 60Hz – 3 Phase

- 380V – 50Hz – 3 Phase

- Multi-profile roll-forming cage

- Standard powertrain

- Standard multi-profile shear blade and die kits

- Beck Automation SII control system with color touch-screen display

- Fast rolling cage adjustment for shifting between profile sizes

- 6500-lb (2,950-kg) powered decoiler with automated coil feed speed control

- Flange dimpling punch toolkit

- Web service hole punch toolkit (1.50 x 3.00 in., 38 x 76 mm)

- 1-year limited warranty

- Thickness range: Ga. 20 – Ga. 14 (0.84 mm – 1.9 mm)

- Multi Profile: Web 3.63, 4.00, 6.00, 8.00, 10.00, 12.00 in.

- Multi Profile Flange: 1.63, 2.00, 2.50 in.

- Maxim flange stiffener length: 0.75 in. (19 mm)

- SFIA/SSMA standard profiles

KFS Framemaker 1420G2

- 460V – 60Hz – 3 Phase

- 380V – 50Hz – 3 Phase

- Multi-profile roll-forming cage

- Standard powertrain

- Profile-specific shear blade and die kits

- AMS control system with ScotRF interoperability

- Fast rolling cage adjustment for shifting between profile sizes

- 6,500-lb (2,950-kg) powered decoiler with automated coil feed speed control

- Flange dimpling punch toolkit

- Web service hole punch toolkit (1.50 x 3.00 in., 38 x 76 mm)

- Large service hole web punch toolkit

- Web shear tab connection punch toolkit

- Inkjet Labeling Printer

- Spare parts kit (2-year supply)

- 2-year limited warranty

- Thickness range: Ga. 20 – Ga. 14 (0.84 mm – 1.9 mm)

- Web depth options: 3.63, 4.00, 6.00, 8.00, 10.00, 12.00 in.

- Flange width options: 1.63, 2.00, 2.50 in.

- Maximum flange stiffener length: 0.75 in. (19 mm)

- SFIA/SSMA standard profiles

Features

Brochures & Resources

KFS Framemaker 1622 Brochures & Resources

KFS Framemaker 1622G1

- 460V – 60Hz – 3 Phase

- 380V – 50Hz – 3 Phase

- Standard Multi-Profile Shear Blade/Die Kits

- Standard Power Train

- Beck Automation SII Control Kit

- Manual Rollformer adjustment

- #6500 Decoiler

- Slot Tool (1.50 x 3.00)

- Multi-Gauge: 22 to 16 Ga

- Multi Profile: Web 3.50, 3.63, 4.00, 5.50, 6.00, 8.00

- Multi Profile Flange: 1.63, 2.00, 2.50

- Max return: 0.75

- SFIA Standard Profiles

KFS Framemaker 1622G2

- 460V – 60Hz – 3 Phase

- 380V – 50Hz – 3 Phase

- Standard Power Train

- Profile-Specific Sized Shear Blade/Die Kits

- AMS ScotRF Compatible Control Kit

- Manual rollformer adjustment

- #6500 Decoiler

- Dimple Tool

- Slot Tool (1.50 x 3.00)

- Round Hole Tool (Choose Size)

- Optional Web Cut Tool

- Inkjet Printer (Keyence MKG-1000)

- Multi-Gauge: 22 to 16 Ga

- Multi Profile: Web 3.50, 3.63, 4.00, 5.50, 6.00, 8.00

- Multi Profile Flange: 1.63, 2.00, 2.50

- Max return: 0.75

- SFIA Standard Profiles