The Scottsdale steel framing system is a complete light gauge steel manufacturing solution: roll forming machinery; design and engineering software; global 24/7 support.

Light Gauge Steel Framing Systems

A complete steel framing system for light gauge & cold-formed steel fabrication.

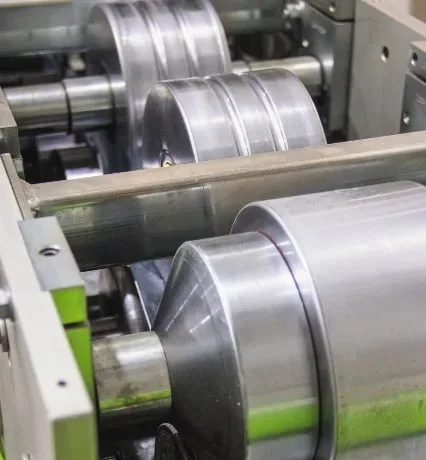

The Scottsdale ecosystem has two major streams in its product offerings. The hardware stream includes roll-forming machinery, decoilers, and associated components for manufacturing cold-formed steel profiles of various dimensions to cater to different parts of the world.

The software stream includes detailing, engineering, roll-forming control, and layout generation software suites that seamlessly integrate with Scottsdale roll formers, facilitating the rapid production of cold-formed steel buildings of various sizes and shapes worldwide.

The Scottsdale Steel Framing System

MACHINES

Engineered for precision and durability, these robust roll forming machines include panel and truss roll formers, as well as decoilers. They are a perfect balance of capability and cost, without unnecessary extras. Every product option in our roll forming range is justified by a capability that adds to your bottom line.

SOFTWARE

Our user-friendly software transforms architectural designs into true 3D layouts for panels and trusses, performs relevant engineering analysis, and readily syncs with the roll formers, guiding production output efficiently and seamlessly.

SUPPORT

We support you as you grow with us, through 24/7 worldwide assistance, maintenance and spare parts, online knowledge base, and design/detailing expertise. Our flexible support package options work for all operator sizes, either tied to how much steel you fabricate, right up to unlimited support plans.

The Complete Steel Framing Equipment & Technology Ecosystem

Technology-Rich Steel Framing System: The Ultimate Construction Automation.

Our technology offers a total enterprise solution and a complete ecosystem for anyone wishing to venture into LGS/CFS steel framing business, or expand their current operations along any dimension of the construction supply-chain. The vast array of rollforming equipment we develop and distribute allows us to meet the most varying roll forming needs and objectives, whether you are a stud and track supplier, CFS/LGS framing fabricator, a homebuilder, steel truss manufacturer, modular fabricator, commercial framer, drywall contractor, roofing contractor, and much more. Whatever your objective, ours is to provide you with the same high-quality equipment system, software, and enterprise solutions.

Speed of Production. Efficiency. High-End Technology. Quick Learning Curve. Ultimate Construction & Framing Automation.

No need to sacrifice power and technology for affordability. We created equipment financing solutions to broaden the number of beneficiaries of our steel framing technology. We also crafted our technology to lower the barrier of entry by allowing any business to quickly adopt our technology, whether it is starting in steel framing anew, expanding current light gage steel framing business, or shifting from wood to cold-formed steel.

Technology

The technology comprises comprehensive virtual building 3D design software and machine control software and CNC rollforming machines.

Scottsdale has two product lines: Panelised Fabrication Systems and Truss Fabrication Systems, although many permutations and combinations are possible, i.e. panels can be used for ceilings, roofs & beams; trusses for floor joists.

The Panelised Fabrication System can build complete Steel Houses Including Walls, Ceiling, Roof Frames & Floor Joists for the residential market. For the commercial construction sector it can be used to build Completed Steel Buildings Including Roofing Panels, Infill Panelling, External Rain Shield & Internal Partitioning.

The Truss Fabrication Systems produces fully engineered bolted steel trusses and floor joists.

These technologies have been developed for the residential & light commercial markets taking account of operational & economic realities, such as the impracticality of transporting wall frames & roof trusses any distance from the point of manufacture. This means low cost rollformers and production rates suitable for 2 to 4 man teams manufacturing & fabricating light gauge steel panels and/or trusses.

Both technologies are software & rollformer based using cold rolled steel from 0.55mm to 1.20mm thickness.

Setting the Industry Standard for Excellence in Steel

Customer Endorsements

“The biggest contribution Scottsdale has made to my business has been in being there when we need them. I live in New Orleans, we operate out of New Orleans, and we have hurricanes and frequent power outages. Every time we have needed Scottsdale to sign back onto our system remotely from New Zealand or Australia, they are there to do it and that has been a lifesaver.”

Chad Brown, Dominion USA, Inc., Founder

“With the cost of housing in Canada homes and with rentable suites as mortgage helpers becoming increasingly popular, Scottdale’s LGS system allows for a complete open concept basement to develop suites. There is a significant shortage of skilled labor in Canada, and Scottsdale’s system allows homes to be built with “unskilled” workers.”

Tom Rus, President & GM, Dominion Metal Frames

“A huge thanks to the Scottsdale Construction Systems team! We are thrilled to have such phenomenal equipment, software, and support being added to our production arsenal. Big things to come from our growing home here in Northwest Arkansas!”

Kyle McGuire, President & CEO, Velent Steel Structures

“In 2021 we received our first Knudson roll-former, and since then we haven’t looked back. Today we operate 3 different Knudsons. We enjoy working with Patrick Flood, J.R., and the rest of the Scottsdale team. The service is great and they’re always innovating.”

Tiago Atwi, Co-Founder, US Frame Factory

“Our relationship with Scottsdale Construction Systems and its steel framing technology is an integral part in our success with clients demanding their framing be Scottsdale Constructions Systems product.”

Jake Gundry, CEO, Australian Framing Solutions

“Total Field & Environmental Services, LLC has become a manufacturing company because of Scottsdale Construction Systems! Our future is brighter today, our quality is better, and more importantly, our productivity has increased tenfold.”

Tony Burke, Owner, Total Field & Environmental Services, LLC