Possibilities with cold-formed steel (CFS) framing are limitless. Commercial structures, single-family and multi-family residential buildings, and even one-of-a-kind projects can all be built with light-gauge steel. Here we highlight several real-world CFS projects designed with our cutting-edge software, ScotSteel and ScotSruct. ScotSteel is a comprehensive 3D modeling software for the design and engineering of light-gauge steel structures within the Scottsdale ecosystem. ScotSruct is an advanced engineering software that performs advanced structural design of light-gauge steel assemblies using cutting-edge methodologies, such as the Direct Strength Method (DSM), ensuring that the design meets the applicable building code and standards. Once a project design has been completed, it is brought to life using the CNC production software ScotRF which powers the advanced Scottsdale roll-forming machinery, used by our customers worldwide. We maintain a vast ScotSteel-designed project library on Sketchfab. Some of these buildings are highlighted in this article, alongside the detailed project information, including the specific Scottsdale roll-forming machines used. Each project demonstrates the precision, productivity, quality, and speed brought to bear by Scottsdale’s advanced roll-forming systems and steel framing technology.

Cold-Formed Steel Commercial Buildings

Cold-formed steel in an ideal material for large-scale commercial and industrial projects due to its strength, versatility, and efficiency. CFS material has a high strength-to-weight ratio making it an ideal option for commercial projects. According to Steel Framing Industry Association (SFIA), “This characteristic allows structures to be both strong and lightweight, making them easier to handle and transport. For example, an 8-foot long 3-5/8 inch, 12-gaguge metal stud can support a load of 8,000 pounds while weighing only 20 pounds itself.” This section highlights several light-gauge steel projects showcasing the diverse applications of the material in constructing robust and reliable commercial structures.

Indoor Recreational Space

The “Cold-Formed Steel Commercial Building – Gun Range” project, located in the United States, is an 18,393-square-foot commercial facility. The roof of the building features a gable design, which is common for commercial structures, providing efficient water drainage and structural support. The span length is impressive, designed to accommodate the expansive layout of a gun range. The roof structure is framed out using light-gauge steel trusses, offering both strength and flexibility. This makes it an ideal system for large open spaces, ensuring maximum material efficiency while maintaining structural integrity. As for the interior, the building is divided into several functional rooms, including the main gun range area, office spaces, storage rooms, and designed safety areas for noise control and operational purposes. The overall design maximizes space efficiency while supporting the specific needs of a gun range facility. Fully designed in Scottsteel, roof framing fabricated using our automated truss roll forming platform Scottruss 6050, while the remainder of the structural framing was produced with our popular roll former Scotpanel 5140.

Hospitality Projects & Hotels

The “Cold-Formed Steel Commercial Building – Tapestry Hilton V6” project, located in Canterbury, NZ, is a 10,120-square-foot expansion of an existing hotel. This project involves the addition of two levels to the existing hotel, enhancing its capacity and functionality. The CFS structure was manufactured using a Scotpanel 7090 roll-forming system, which fabricated interior and exterior walls and the floor truss system. To address the lateral-force resisting system of the structure, the building incorporates CFS shear walls designed to resist wind and earthquake forces. This project is an example of a modern approach to expanding existing commercial buildings with light-gauge steel material, providing an efficient and high-quality solution to meet growing hospitality demands.

Commercial Building

The “Cold-Formed Steel Commercial Building – Admin Building Amended V2” project, located in Melbourne, AU, is a 2,670-square-feet CFS commercial structure. The roof type is a simple sloped design. The truss system, interior and exterior walls are of CFS material and were manufactured using Scotpanel 7090 and Scottruss 6050 roll-forming machines. At one end of the building, tall ceilings are featured, adding a sense of openness and spaciousness that are ideal for reception rooms, offices, or common areas. Light-gauge steel material allowed architects and engineers the design flexibility needed to meet both functional and aesthetic requirements of a modern commercial building.

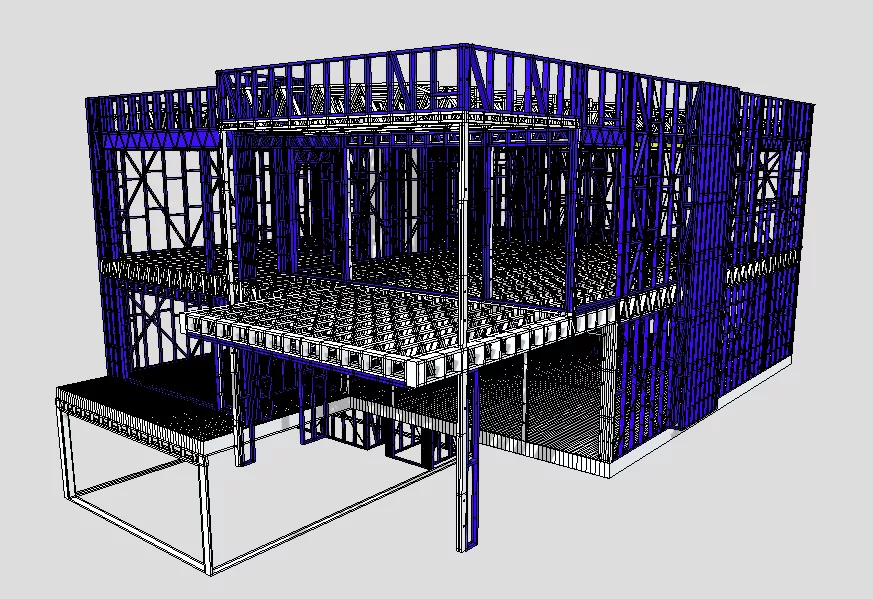

Commercial Building with Mezzanine

The “Cold-Formed Steel Commercial Building – Brian Kirkwood” project, located in Washington, USA, is a 2,490-square-feet CFS commercial development. This project showcases a commercial space, leveraging advanced light-gauge steel framing technology to deliver a durable and reliable structure suitable for its commercial purpose using Scotpanel 7140 and Scottruss 6050 roll-forming machines. It features high ceilings ideal for versatile commercial applications. The building includes a mezzanine level, adding to its usable space while maintaining an open feeling. The roof is a sloped CFS roof system. Additionally, the large openings at the entrance are important to highlight as a design feature achieved with light-gauge steel material.

Cold-Formed Steel Residential Building – Single Family Homes

Cold-formed steel is a great building material for residential homes, offering fast, affordable, and sustainable solutions to today’s housing challenges. Steel homes can be manufactured and constructed in just days, depending on design complexity, size and crew size. For instance, a 1,500-square-feet single-story home was assembled in two days by two employees with no prior steel framing experience. Remarkably, the same two workers erected the entire structure without the need for forklifts or cranes, completing the entire project in just four days. To learn more about the benefits of steel homes, read our previously published article “Steel Homes: An Affordable Solution to the Housing Crisis”. Several light-gauge steel single-family home projects are showcased with detailed information on the roll-forming machines used to manufacture the building components.

Single-Story Family Homes

The “Cold-Formed Steel Residential – Grant Burton” project, located in North Brisbane, is a 2,140-square-feet residential light-gauge steel design. This steel home has a CFS gable roof, offering a traditional single-family home aesthetic with the added benefits of CFS material using Scotpanel 7070 and Scottruss 6050. A two-car garage is integrated into the structure in addition to a covered patio that extends the living space outdoors. Large windows and openings are incorporated into the design of the steel home, creating a flexible and spacious living environment.

The “Cold-Formed Steel Residential – Lot 6 Christie St V3” project, located in Exmouth, WA, is a 1,670-square-feet CFS residential building. This home has a gable roof in addition to a covered carport, all manufactured of CFS material using Scotpanel 7090 roll-forming machine. The project exemplifies how light-gauge steel can be used to build steel homes without compromising on the traditional aesthetics of a home.

Luxury Two-Story Residential Building

The “Cold-Formed Steel Residential – SK-01A” project, located in the Caribbean, is a luxury CFS residential development with a distinctive curved architectural exterior, which adds a dynamic, fluid aesthetic to the home. The rooftop patio in addition to the covered patio give this home ample outdoor space. The architectural spiral staircase creates a focal point and adds elegance to the design of this luxury light-gauge steel home. This unique project is a great example of what can be achieved with CFS material and Scotpanel 7090 roll-forming machine.

Two-Story Residential Building with Basement

The “Cold-Formed Steel Residential – Alan St 4” project, located in Adelaide, AU, is a CFS multi-story residential building with basement. The roof, floor, interior and exterior walls are all light-gauge steel material. Our state-of-the-art roll-forming technology provides design flexibility for CFS floor and roof truss systems, making it easy to accommodate HVAC systems seamlessly. This project was manufactured using Scotpanel 7090 roll-forming machine.

Two-Story Residential Cabin

The “Cold-Formed Steel Residential Cabin – Cabin 2” project, located in Belgrade, MT, is a unique CFS residential structure design which incorporates a sub-floor truss system. The project was manufactured using Scotpanel 7090 and Scottruss 6050 roll-forming machines. This project stands out for its thoughtful engineering and innovative use of light-gauge steel materials, making it ideal for residential applications.

Small Residential Building

The “Cold-Formed Steel Residential – Blip 2” project, located in North Carolina, USA, is a compact 576-square-feet CFS residential building manufactured with Scotpanel 7090 roll-forming machine. Suitable for urban living or an addition to existing structures, this project demonstrates a modern approach to smaller-scale living, offering a functional and efficient living space while maintaining top-quality construction standards with light-gauge steel framing.

Cold-Formed Steel Residential Building – Multi-Units

Another ideal cold-formed steel building application is in urban development, particularly in construction of multi-story residential buildings. A prime example of its capabilities is the SFIA Masten Tower, a 40-story residential apartment built using light-gauge steel framing. Urban development often faces challenges such as site storage and logistics, but these can be effectively addressed with containerized roll-forming factories or by modular construction. Our roll-forming machines, designed with a compact footprint, can operate directly from inside a container with a decoiler, providing urban job sites with the efficiency and flexibility needed in tight spaces. For more insights on how CFS can transform urban development, visit SFIA’s article “How High Can You Construct a Building with Cold-Formed Steel Framing?” In this section, we’re showcasing a selection of light-gauge steel multi-unit residential projects, along with detailed information on the roll-forming equipment used to manufacture each structure.

Multi-Story Apartment Complex

The “Cold-Formed Steel Residential Development – Building Type 1” project, located in Jackson, TN, is an 8,110-square-feet light-gauge steel residential development. This project features one building containing seven residential units and an administration block, making it a versatile, functional and multi-use CFS development. The project was manufactured using Scottsdale Construction Systems’ Scottruss 6050 (for truss system), Scotpanel 7090 (for exterior walls), and Scotpanel 7140 (for interior walls) roll-forming machines.

Two-Story Townhomes

The “Cold-Formed Steel Residential – Block 1” project, located in Australia, is a 3,970-square-feet light-gauge steel residential development. The building was manufactured using Scottsdale Construction Systems’ Scotpanel 7090 for the exterior walls and Scottruss 6050 for the truss system, ensuring superior durability and precision in CFS design and engineering.

Two-Story Duplex

The “Cold-Formed Steel Residential – Duplex 2 Levels” project, located in Barbados, features a well-designed 1,572-square-feet CFS residential structure. This duplex incorporates advanced construction techniques using Scottsdale Construction Systems’ Scotpanel 7090 roll-forming machine. The two-level light-gauge steel residential layout maximizes space, offering a modern and efficient living environment.

Unique Cold-Formed Steel Projects

Our roll-forming machines have been utilized for a wide range of unique and innovative projects, showcasing the versatility of cold-formed steel. From manufacturing framing members for additions to existing buildings, constructing A-frame cabins in harsh environments with heavy snow loads, and building exhibit booths, shower sheds, and even architectural sculptures, cold-formed steel material can be used to construct a diverse scope of structures. Beyond the commercial applications, our roll-forming equipment can support humanitarian efforts, including the manufacturing of small housing in crisis regions. The adaptability of CFS material makes it an invaluable tool for both creative and practical solutions in various industries. A few examples of these projects are listed in this section in addition to the roll-forming equipment used to manufacture the light-gauge steel building members.

Penthouse Addition

The “Cold-Formed Steel Residential – 6 Module” project, located in Scotland, is a CFS residential development with 6 transportable CFS modules for a penthouse on an existing multi-story. These light-gauge steel modular units are designed for easy transportation and efficient assembly on an existing structure. This project was manufactured using Scotpanel 7090, Scotpanel 5140, and Scottruss 6050 roll-forming machines.

A-Frame Building

The “Cold-Formed Steel Residential A-Frame Building” project, located in Denver, Colorado, presents a compact yet functional 575-square-feet A-frame cabin designed for holiday or residential use and manufactured using Scotpanel 7090 roll-forming machine. This design emphasizes simplicity and modern aesthetics with the iconic A-frame structure using CFS framing. The project highlights how our roll-forming machines can be used to design and build personal or vacation light-gauge steel homes.

Exhibit Booth

This booth structure, encompassing all major building elements was assembled for the 2025 National Association of Home Builders (NAHB) International Builders’ Show (IBS) in Las Vegas, NV. This project shows how our roll-forming machines can be used to manufacture and build any project type using a variety of our machines including: Scotpanel 7090, Scottruss 6050, and Knudson by Scottsdale KFS Framemaker 1420.

Enclosed Pool Shower

The “Cold-Formed Steel Small Structure – Pool Shower” project is a unique design created for outdoor spaces, offering an ideal solution for residential or recreational use. With a compact footprint of 103-square-feet, this light-gauge steel structure provides a convenient and functional shower space near pools or patios. This design shows versatility in creating practical yet stylish outdoor features and add-ons to existing structures using CFS material and Scotpanel 7090 rollforming machine.

Architectural Sculpture

Scottsdale Construction Systems’ roll-forming machinery can also be used to create art and sculptures. Our customers have used the Scotpanel 7090 to combine artistry with engineering to create art. The advanced technology of our roll-forming equipment and our state-of-the-art software ensures high customization and efficiency, making it an asset in producing both structural and decorative steel components for modern construction projects.

Our roll-forming machines support a wide variety of projects, ranging from residential, commercial, industrial, and even more unique projects. Whether your project is large or small, Scottsdale Construction Systems’ roll-forming machines can provide a solution. As a global company, we provide dedicated support to our customers, enabling them to build almost anything with cold-formed steel. Learn more about our roll-forming equipment by contacting us at sales@scottsdalesteelframes.com or call us at +1 (888) 406-2080.