Delays in sourcing cold-formed steel (CFS) components can severely disrupt construction projects. Builders who rely on external suppliers often face setbacks from stock shortages, transportation delays, or miscommunications. These issues result in lost opportunities, missed deadlines, and ultimately, businesses lose market competitiveness. Businesses can avoid these setbacks by fabricating their own cold-formed steel components in-house. In this article, we will explore the key benefits of bringing CFS fabrication in-house.

Taking Control of Project Schedule & Material Sourcing

Fabricating CFS components internally gives builders control over both schedule and material sourcing. Instead of relying on suppliers, they can produce the exact components needed without the wait time. This not only keeps builders on schedule but also eliminates the risk of delays that suppliers cause. Additionally, in-house CFS fabrication allows builders to customize components to the precise dimensions required, allowing design flexibility, incorporating service holes and other features as needed for each job—something that’s difficult or costly when modifying stock pieces from suppliers.

With in-house CFS fabrication, builders are in full control of their projects. Our roll forming equipment are a series of standalone hydraulic tools, including shear and a group of punch presses which are used to process predefined components. These tools allow for quick adjustments and precise modifications, keeping projects on track. Our customers can fabricate the steel components needed for sheds, garages, and other framing projects without relying on external suppliers. By bringing CFS fabrication in-house, businesses can stay competitive and streamline operations.

Better Quality of Product with Advanced Roll Forming Equipment

When sourcing from suppliers, builders are limited to available stock pieces and modifying them consumes resources and time. Fabricating their own components ensures higher quality of material and greater precision. The incorporation of computer-aided design (CAD) into rollforming further reduces material waste and errors. CAD enables precise control over design and directly feeds production details to the machines, resulting in accurate, ready-to-assemble components with minimal manual intervention.

End-To-End Cold-Formed Steel Solutions

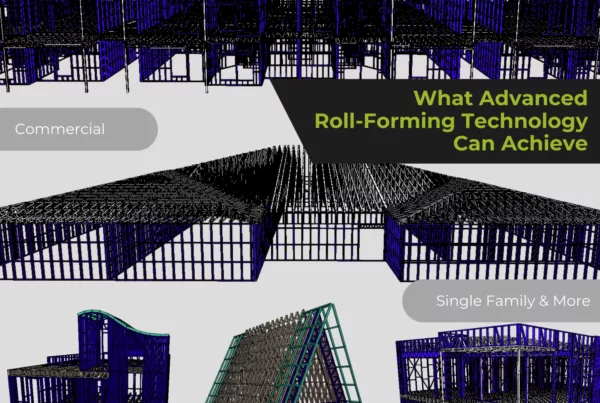

Knudson has a long history of innovation when it comes to metal-working machinery. The company began manufacturing the first portable rollforming machines for making gutters on jobsites back in 1957. Within a few years, the company had developed machines that formed roof panels, fascia, soffit, and valley panels. Knudson has since switched focus mainly to cold-formed steel framing components in North America. Knudson offers two main roll forming models, KFD Framemaker and KFS Framemaker. KFD Framemaker is a roll former specializing in light- gauge nonstructural framing elements such as lipped and unlipped channel sections for internal load-bearing and non-load-bearing partitions in office and shop applications. KFS Framemaker is a roll-former specializing in light-gauge structural framing elements for internal load-bearing partitions in residential and commercial applications.

Our high-tech rollforming machines, supported by state-of-the-art software, make it easier than ever to fabricate custom light-gauge steel components. Our design software, ScotSteel, allows for detailed specifications such as length, quantity, dimples, web notching, and flange removal of CFS members. This data can then be integrated within ScotSruct, our structural analysis software, for engineering analysis based on current codes and standards. Once designs are finalized, the data is fed directly to our roll forming equipment using ScotRF, our rollforming and production management software, ensuring each piece is fabricated exactly as specified. CFS components come out ready for assembly, with labels added for easy identification, reducing the chances of assembly errors. For more information, download “Best in Class, Knudson Manufacturing Aids Builders in Pursuit of Excellence”.

Learn more about our rollforming equipment by emailing us at sales@scottsdalesteelframes.com or calling us at +1 (888) 406-2080.