Like cats vs dogs or Ford vs GM, timber vs steel framing is one of those eternal debates that seem to have permanent believers on both sides. Everyone knows the arguments and they’ve stuck to their personal preference … until now.

Global supply chains have been disrupted by pandemic-induced transport and logistics bottlenecks. At the same time, near-zero interest rates, government stimulus and post-lockdown pent-up demand has kicked off inflation, hitting key sectors of the economy and sending timber prices through the roof.

Paying a few extra dollars for your latest DIY home fixit job might not seem a big deal, but construction companies have felt this heavily, with delayed projects and profits burnt across the board.

So how does steel framing stack up as an alternative?

In 2021 we should leave the usual arguments aside and look solely at cost and supply. Cost comparisons for light gauge steel or timber framing previously came up about even through the whole project cycle. But as timber prices rise (exponentially in some markets), many builders and timber truss and frame suppliers are looking to add steel to their offer as a way to stabilise costs, spread risk and meet demand. Steel prices have also risen in some markets, but not at the same rate as timber.

In terms of supply, rolled coil steel is generally proving more consistent and reliable across markets, helping to fill the gap for those who take it on.

The Scottsdale Ecosystem

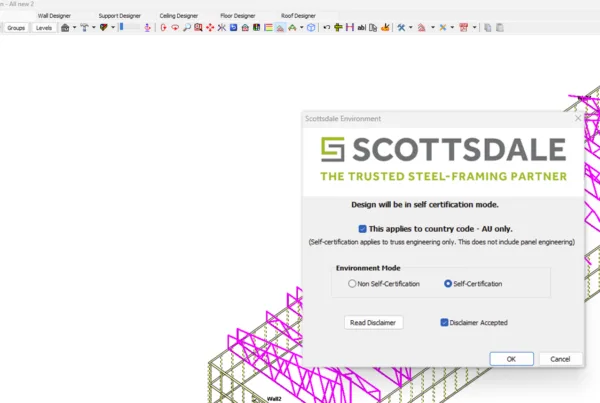

This is where the Scottsdale total steel fabrication “ecosystem” comes in. It comprises the necessary hardware, software and support that together allow us to help you succeed in operating and growing your steel fabrication operations. It includes:

- Panel roll forming and truss roll forming machines

- Design, engineering and roll forming software

- 24/7 support service

- Business setup, know-how and operational support

Does the steel fabrication business pay?

The obvious question before investing in Scottsdale’s Light Gauge Steel fabrication ecosystem is: Can you make it pay?

The answer is a definite “Yes!”, because:

- It’s much more economical to set up a steel framing business than a timber one. For a start, it doesn’t need nearly as much space.

- You can make a rapid ROI in the current white-hot market.

Payoff example 1:

A single roll former supplying 4 houses per month

A new steel framing fabrication business, supplying steel framing for 4 houses per month can make sufficient net profit in the first year to fully repay the capital expenditure with capacity for further upside. Capital expenditure paid off in Year 1 includes:

- one machine plus software (delivered)

- training and commissioning

- office and factory fit out

- factory equipment

- stock.

Meanwhile in the USA, where lumber prices have increased by up to 3-fold, steel is still readily available. “Conditions are especially ripe here to invest,” says Scottsdale US Sales Manager Derek McSpadden. “And with our operational experience and business know-how, we can fast track your ROI.”

Payoff example 2:

Two roll formers providing capacity for 12 homes a month

Similarly, if you are a builder working at the equivalent scale of 12 houses per month, having your own frame and truss machines you can make a saving of over $1,000,000 per annum of frame and truss supply.

Plus, you’ll also find:

- Your machine’s spare capacity can fabricate extra profit from other, smaller builders.

- If there’s a problem on site such as a design adjustment due to an error by another contractor, you can make the required changes more easily, economically and quickly.

- You can produce when you want; no worries about supplier errors or waiting your turn when they are busy.

The Scottsdale calculator: a solid assessment tool

No matter where you are in the world, or what your current business situation is, you can quickly evaluate the feasibility of getting into steel framing with our special calculator tool.

When you book a call or appointment with us, we can take you through line by line to show what the ROI looks like for your circumstances. If it’s not right for you, that’ll be clear to both of us. As the calculator is based on our decades of business know-how and management experience, you’ll quickly find out if it’s a green light. And from there, we’ll give you a copy of the calculator so you can play around with different scenarios to come to the best possible decision.

We do better when you’re winning.

Talk to us and build in the benefits

Even if timber prices go down eventually, you’ll have a more diverse, flexible operation that can quickly adjust to circumstances, meet demand and keep your customers happy.

To learn about Scottsdale Steel Framing Solutions or to book a calculator session with one of our team, enquire now.

For more information on the range of roll formers, including detailed specification, pricing and availability, get in touch with our team and request an info pack.