Lightweight steel frame floor joist installation

All light weight steel frame floor joists should be installed as per the layouts supplied and in conjunction with the architectural drawing and in accordance with engineer’s connection details. Paying special attention to set down, plumbing locations and penetrations.

Sheet flooring installation

As per the particle board manufacture’s installations guidelines and recommendation only. Flooring specific glue should only be used and we recommend the below.

Bostic – Ultra set SF flooring – Ultraset® SF | Hardwood Adhesives | Bostik | Bostik Australia Sikaflex – T55 flooring adhesive – SikaBond® T-55 J

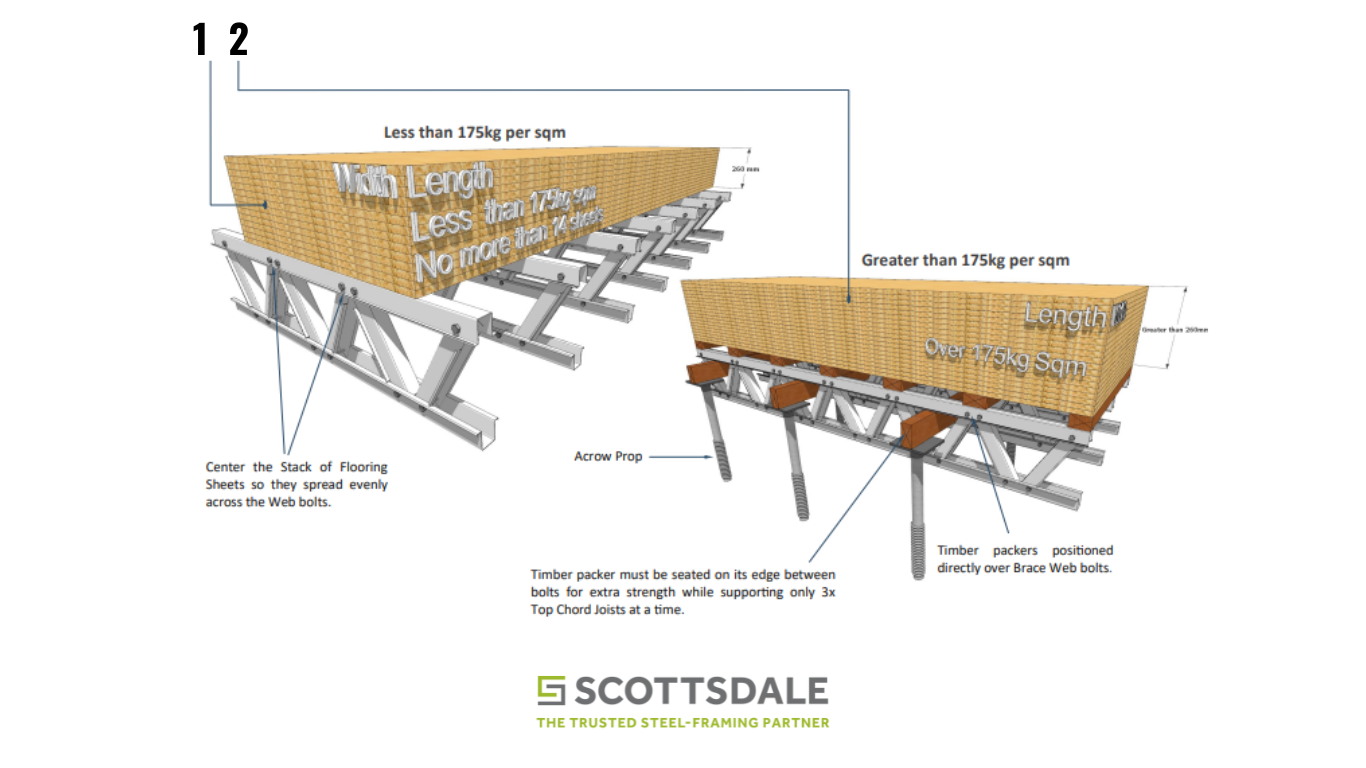

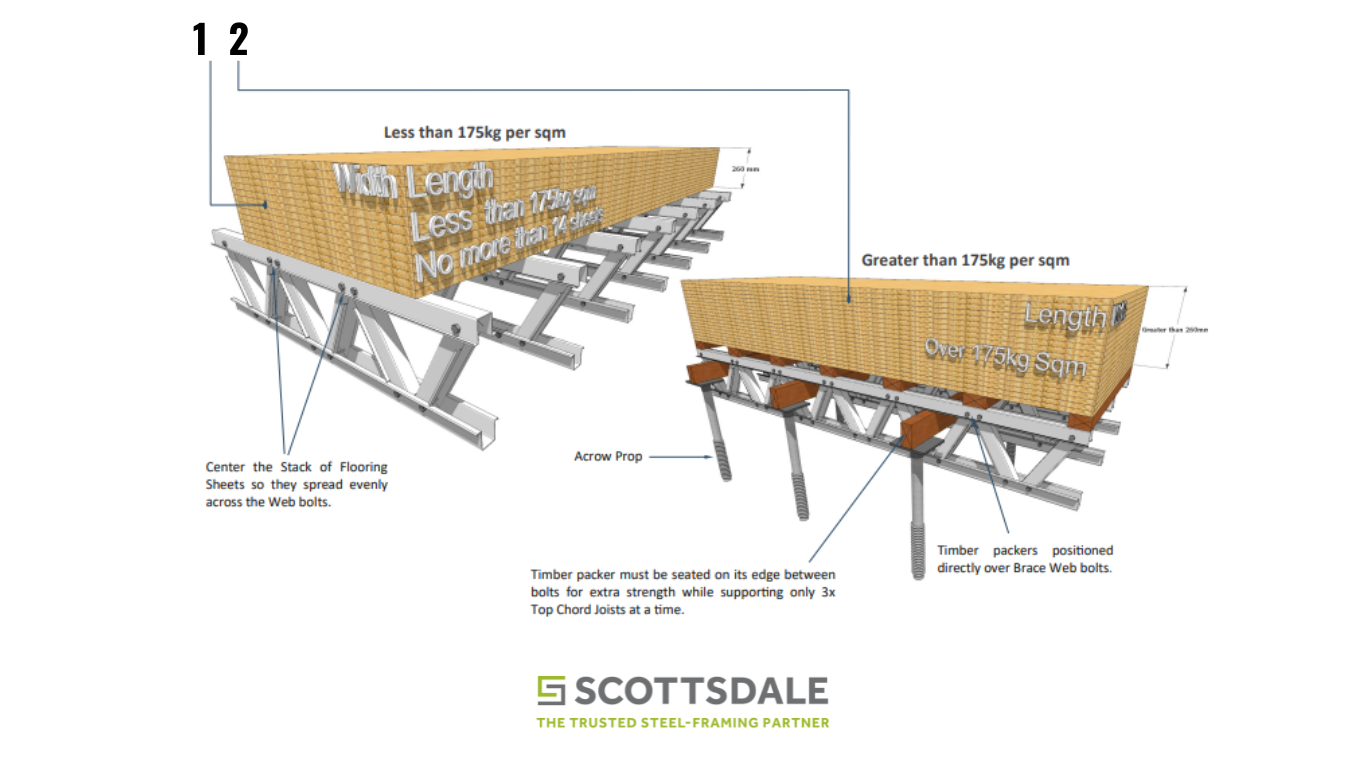

Maximum loading of floor systems

(GRAPHIC 1) The maximum load of materials i.e. temporally stored on an SCS Parallel Chord Joist systems is not to exceed 175kg/m2. This equates to a maximum of 14x 19mm flooring sheets (260mm deep) of 19mm particle board flooring in any given location.

Sheets should be laid lengthways perpendicular to the floor joists where possi[1]ble to ensure maximum load distribution.

(GRAPHIC 2) Should any given load weight be greater than the 175kg/m2 propping must be installed directly below the load point with a minimum of 1 x acro props & 1 x timber supporting member per m2 supporting no less than 3 floor joists and directly between Brace/Web bolts as shown below.

Should multiple loads be applied the above must be repeated for every m2 of load exceeding 175kg/m2.

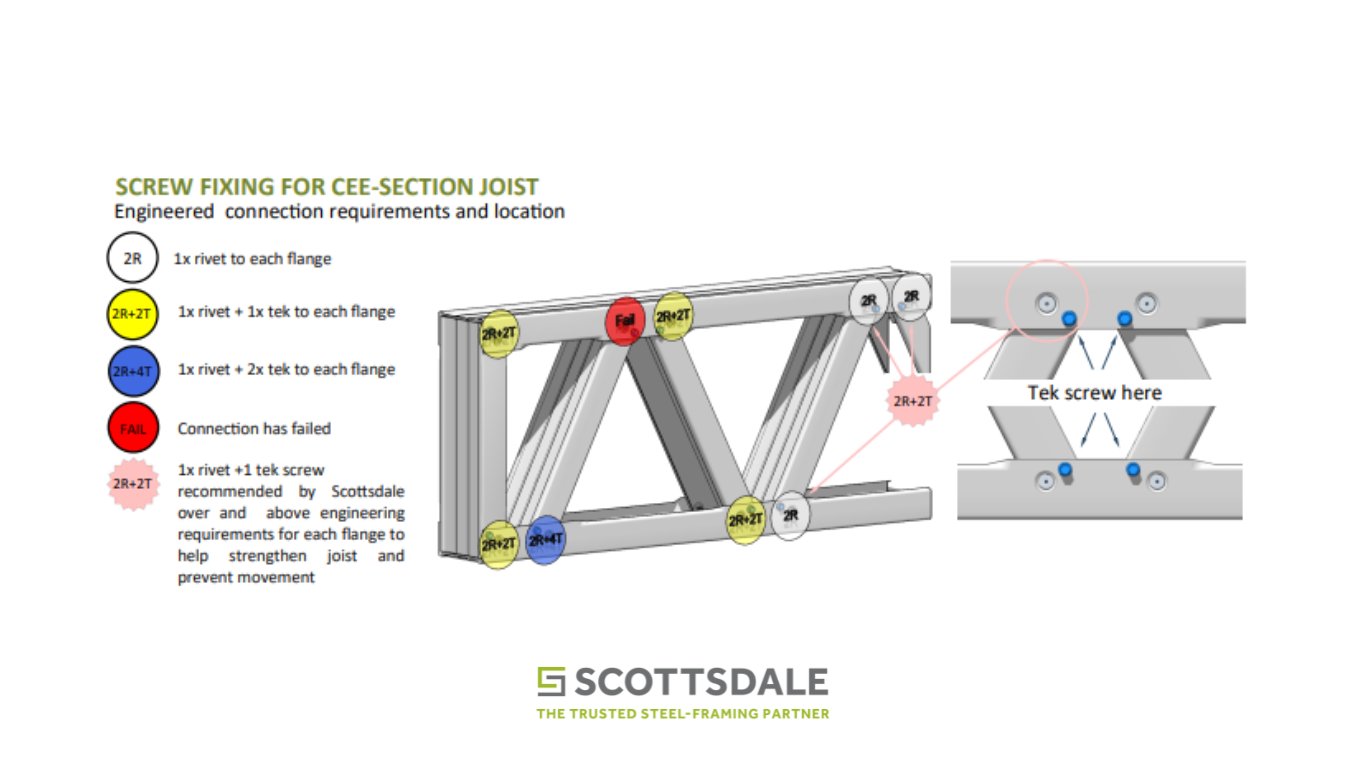

Screw fixing for CEE-Section joist

Engineered connection requierements and locations

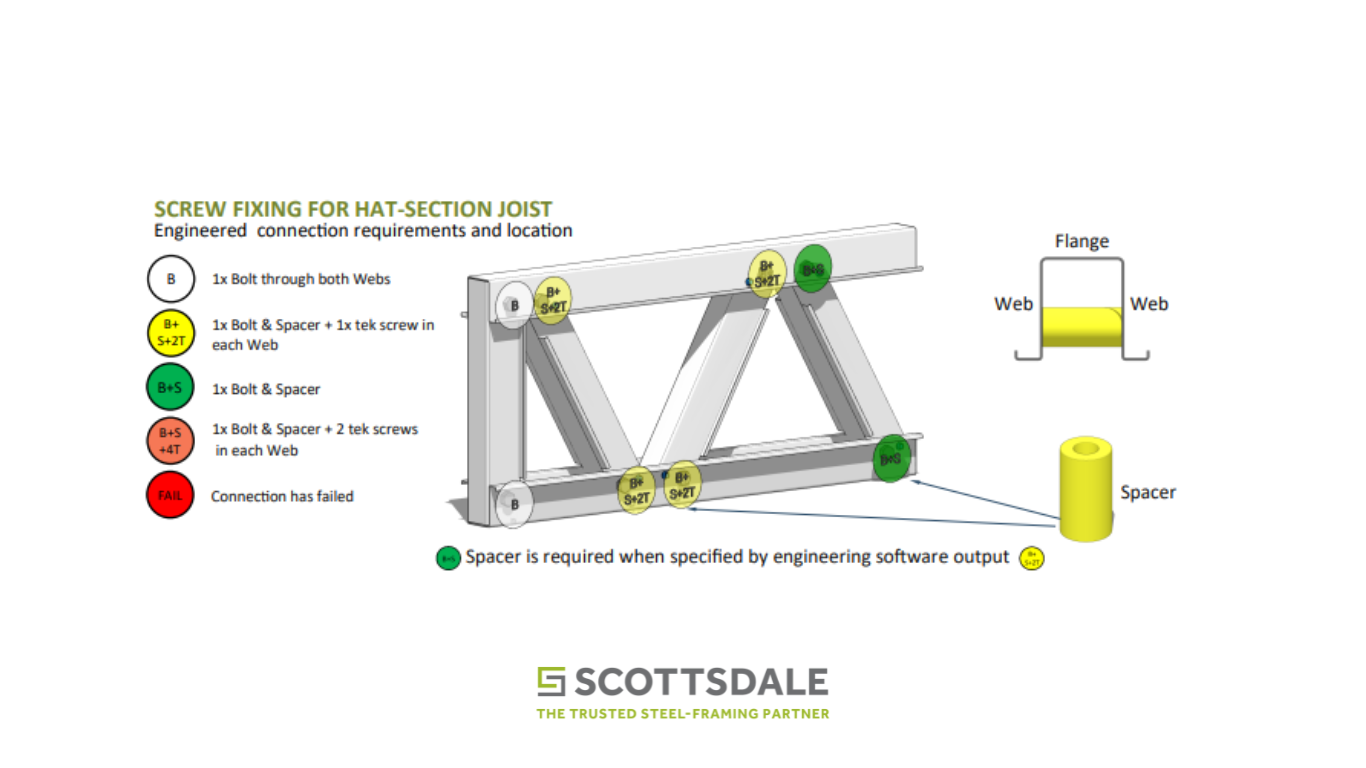

Screw fixing for hat section joist

Engineered connection requierements and locations

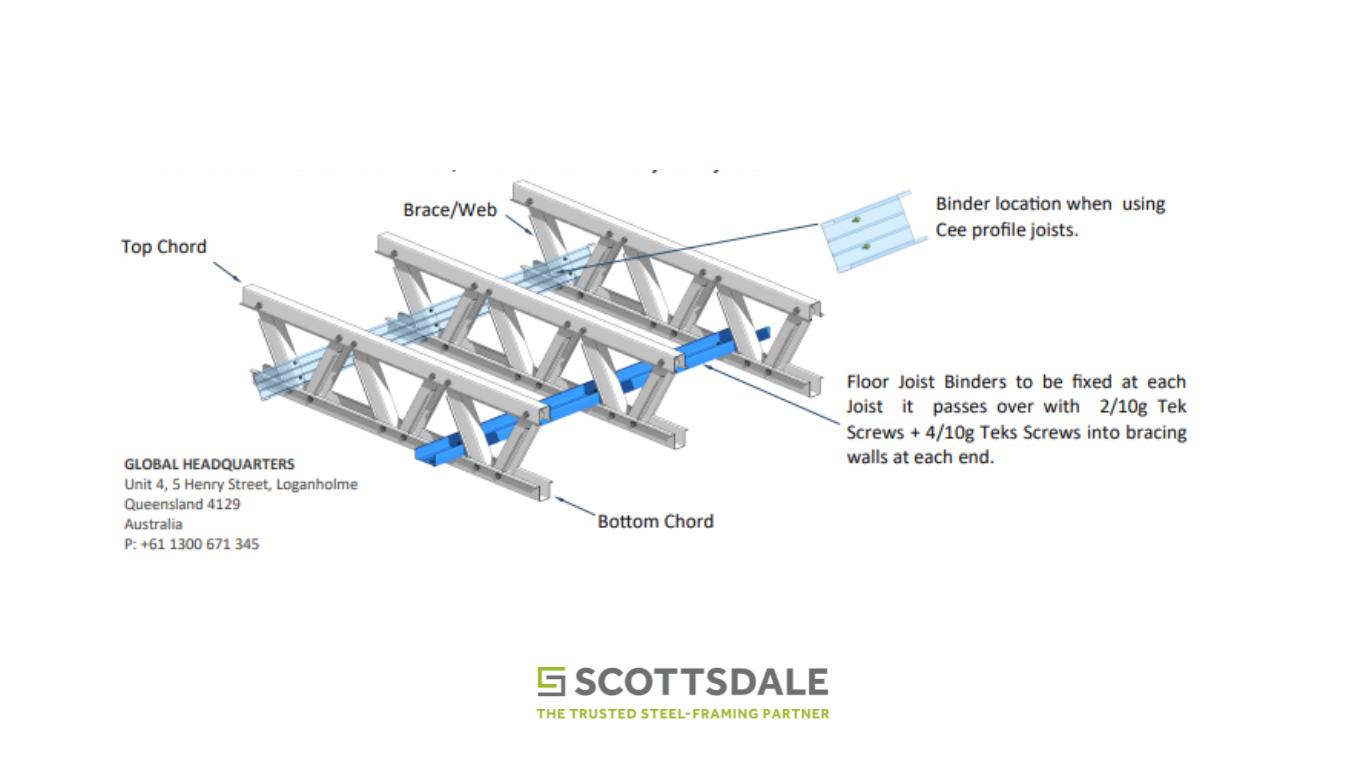

Binding all floor bottom chors

Spans greater than 4.5m require some form of Binding material Mid Span. Can be Hat or Cee profile. Below shows Binder being fixed to Hat profile Lips. For Cee-profile Joists you may have to screw to the bottom of each Brace/ Web that is common to other Brace/Web members on adjacent joists.

Things to help improve floor performance

- Make sure you have at least 3mm physical joint clearance between Web/Brace and Top Chord. To adjust this go into roll former and adjust Joint Clearance in rollformer settings. This maybe more evident when using end bearing.

- If using a caulk gun make sure you have a generous amount of glue forming S trail of bead glue.

- Where 2x floor sheets meet make sure you have 2x beads or a more generous amount of glue to accommodate both sheets.

- C-Section Floor Joists require 1x tek screw next to each rivet to improve strength, (covered on page 2).

- Increase Gauge from 0.75 to 0.95.

- Decrease Panel Size so you have more connections.

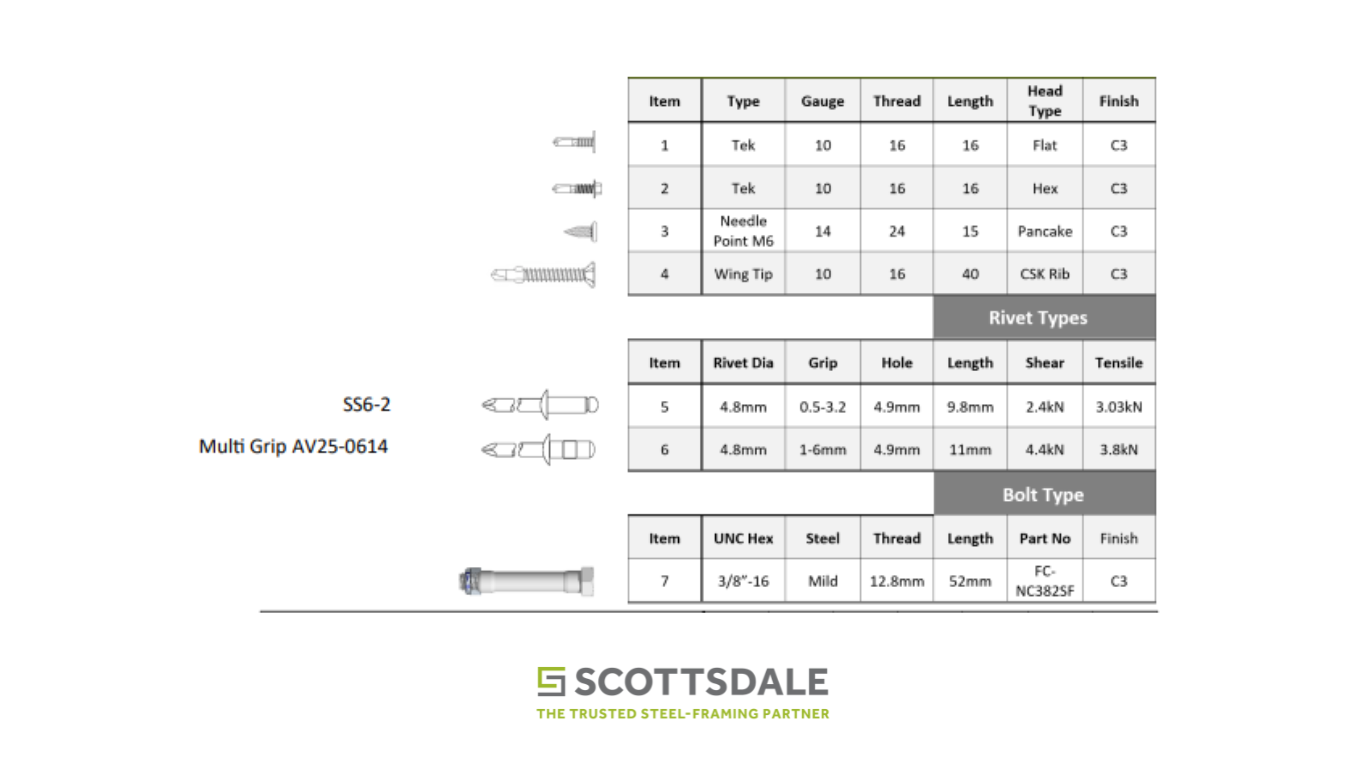

Screw types

Scottsdale, Customer First

Need assistance with your floor joist or sheet flooring installation? Our expert team is here to help! Contact us today for personalized support and ensure your project meets all guidelines and performs optimally. Let’s make your installation seamless together!

To learn more about Scottsdale’s products, including steel frame technology, roll forming machines, steel frame software, and our wide range of offerings, contact us at sales@scottsdalesteelframes.com or call one of our experts at +1 (888) 406-2080 or + 61-1300 671 345.