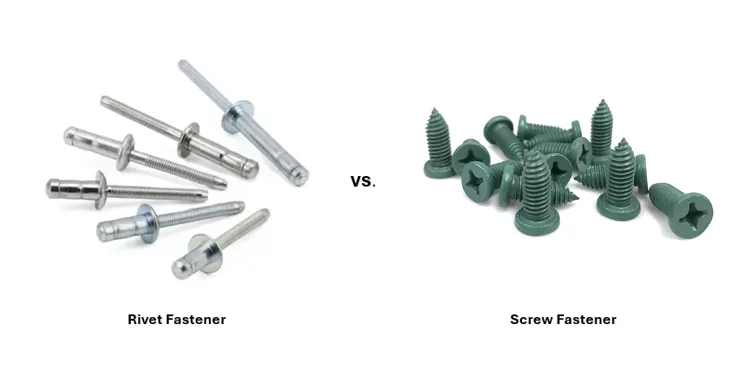

In cold-formed steel (CFS) construction, fasteners are critical in ensuring structural integrity, ease of fabrication, and long-term performance. Two of the most commonly used fasteners in light-gauge construction are rivets and screws. At Scottsdale Construction Systems, rivets are the standard connection type used in our cold-formed steel framing process, particularly 4.80 mm diameter rivets, designed to work seamlessly with our automated roll forming production process. However, screws remain a popular alternative due to their versatility in field adjustments and temporary structures.

This article provides a comprehensive comparison between rivets and screws, covering their use in fabrication, behavior during handling and transport, and relative performance in both light and heavier gauge steel. Whether choosing a fastening method for a prefabricated steel framing or assessing structural demands, understanding these differences will help you make informed, project-specific decisions.

Introduction to Cold-Formed Steel Fastener Types

What are Screws?

Screws are threaded fasteners designed to join materials by cutting into them as they’re driven, typically using a screwdriver or power drill. Unlike rivets, which form a permanent bond, screws offer a removable connection—making them ideal for applications that may require disassembly or future adjustments. Their helical thread provides holding power by creating friction and mechanical interlock within the material, especially effective in wood, plastics, and metals. Self-drilling variants like screws can penetrate thin steel without pre-drilled holes, streamlining installation. While screws can deliver strong and reliable joints, their performance depends on material thickness and the direction of applied loads; under vibration or shear, they may loosen over time unless supported by locking features or adhesives.

What are Rivets?

Rivets are permanent mechanical fasteners used to join two or more materials, typically metals, by passing through aligned holes and deforming the tail end to create a secure hold. Unlike screws, rivets do not rely on threads or rotational force to maintain their connection. Instead, they work by forming a tight clamping force as the shaft expands and locks in place. This makes them especially effective in high-vibration environments where fasteners must not loosen over time. Rivets are often preferred in applications requiring long-term durability, such as aerospace, automotive, and prefabricated steel framing, because they distribute loads evenly and are resistant to loosening or fatigue failures. However, once installed, they cannot be easily removed without damaging the surrounding material, which limits their use in adjustable or temporary assemblies.

When to Use Screws vs. Rivets in Steel Construction

We provide a detailed comparison between rivets and screws, two commonly used fasteners in steel framing and fabrication. We explore how each performs in various aspects such as ease of fabrication, installation methods, structural capacity, and suitability for different project types. By examining their advantages and limitations in both light and heavy gauge steel applications, we aim to help fabricators, engineers, and builders make informed decisions about when to use rivets vs. screws based on specific performance requirements and construction contexts.

Ease of Use in Steel Framing Fabrication

Rivets are generally considered easier and more practical to use in the frame fabrication process compared to screws. This is largely because most roll forming machines, such as the ones used in automated steel framing systems, are designed to punch a hole for the rivet during the manufacturing process. This pre-punched hole allows for quick and accurate rivet placement.

Screws are self-drilling and require the fabricator to manually place them, which introduces variability in position and alignment depending on the operator’s skill and precision. However, when it comes to modifications or on-site adjustments, screws offer an advantage. They can be removed and replaced using a drill, while rivets must be drilled out, which takes time and can damage the surrounding material if not done carefully.

Watch how quickly and effortlessly cold-formed steel framing members are riveted by clicking on the 2025 Cold-Formed Steel Engineers Institute Expo highlight video below.

Performance During Handling and Transportation

Rivets provide a more secure and vibration-resistant connection compared to screws. A key reason is that rivets expand to fill the hole and lock the connected members from both sides, effectively creating a tight and immovable joint. This makes rivets particularly advantageous for prefabricated frames shipped over long distances or subjected to rough handling, as they reduce the risk of joint loosening or structural integrity loss during transit. Rivets provide a more secure and stronger connection and are recommended in permanent structures.

Screws have a head on only one side, which can loosen over time, especially when exposed to continuous vibration during transportation. As this is more versatile, screws can be used in temporary or removable structures.

Performance and Connection Capacity

Thin-Gauge Steel Framing

While the individual tensile or shear capacity of a standard rivet is lower than that of a screw, the overall performance of riveted connections can be quite comparable in light-gauge steel applications. For steel thicknesses commonly used in cold-formed steel framing, typically 0.55 mm to 0.75 mm, the limiting factor in connection strength is often the steel sheet itself and not the fastener. In these cases, whether using rivets or screws, the failure mode is more likely to be tearing or deformation of the steel around the connection rather than fastener pull-out or shear failure. Therefore, both riveted and screwed connections can deliver similar structural performance in thin-gauge steel framing.

Heavier Gauge Steel Framing

When working with heavier gauge steel, typically 0.95 mm thick or more, the performance differences between rivets and screws become more pronounced. Standard rivets may not achieve the same load-carrying capacity as screws in this thickness range due to the higher demands on the fasteners. However, structural rivets, which are engineered for higher loads and greater shear and tensile capacities, can outperform screws in this context. In such cases, the failure mode may shift from the steel sheet to the fastener, particularly with high-strength structural rivets. This highlights the importance of selecting the appropriate fastener type based on material thickness and structural requirements.

Preferred Fastener Type for Scottsdale’s Roll Forming Solutions

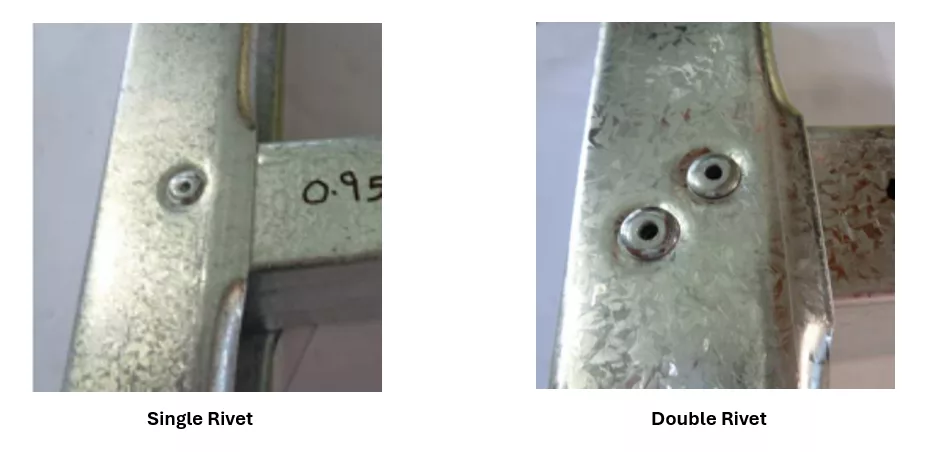

There is ongoing discussion around the use of rivets vs. screws, not only in the light-gauge cold-formed steel industry, but also in other sectors such as aerospace, where rivets are often preferred for their reliability and strength. In the Scottsdale ecosystem, we primarily use 4.80 mm diameter standard rivets to connect C-sections, offering a consistent and secure fastening method. Scottsdale offers both single and double rivet configurations, as illustrated in the figure below.

This video shows a typical rivet attachment operation utilizing framing produced using Scotpanel 7090. For more information on rivet sizing, please refer to the Scottsdale Knowledge Base and view our guide to “Rivet Sizes”.

Scottsdale Automates Rivet Placement for Reliable Steel Framing

In Scottsdale’s cold-formed steel framing system, rivet placement is precisely managed through an integrated software and hardware approach. The ScotSteel design software, part of Scottsdale’s ecosystem, determines the exact locations for rivets based on structural requirements. These specifications are then communicated to the ScotRF roll forming software, which controls the machinery to pre-punch 5 mm holes at the designated spots on the steel components. Additionally, a dimple is created at each connection point to secure the fastener and prevent slippage during assembly.

During the assembly process, workers align the steel components so that the pre-punched holes match up. Using pneumatic rivet guns, they insert rivets into these holes, where the rivets expand to form a tight, vibration-resistant connection. This method eliminates the need for manual drilling or measuring, streamlining the assembly process and reducing the potential for errors. The combination of precise software-driven hole placement and efficient manual riveting ensures strong, reliable connections in Scottsdale’s steel framing systems.

Discover how Scottsdale’s Scotpanel roll forming machines automate double-rivet joint functionality to meet specific structural and geometric requirements in cold-formed steel framing. The video below demonstrates how the ScotSteel design platform communicates double-rivet specifications to the ScotRF software, enabling the roll former to execute precise double-rivet joints as needed.

Additional Scottsdale Roll Forming Solutions and Resources

- Video – Advantages of Riveted Steel Framing with Scottsdale’s Technology

- Video – SCS Steel Frame Machine 90mm Roll Former Double Rivet

- Blog – Overcome Steel Framing Fabrication with Swaging in Roll Forming Technology

- Blog – Informative Guide to Different Connections Used in Steel Framing

- Blog – Everything You Need to Know About Light-Gauge Steel Seated Connections

- Financial Services

For more information or questions on this topic, reach out to us at sales@scottsdalesteelframes.com, or call +1 (888) 406-2080 (Option 1) or +61 1300 671 345. Our team of experts is ready to support you in setting up your own cold-formed steel manufacturing facility.