Steel Codes and Industry Standards

Don Allen, P.E., S.E., brings over three decades of expertise in cold-formed steel (CFS) framing, a material that continues to gain traction in construction projects around the world. Allen’s extensive experience spans across key global markets including the United States, Rome, and Nigeria, contributing to the growth and adoption of CFS in diverse applications. In August 2024, he took on a pivotal new role as the executive director of the Steel Framing Industry Association (SFIA).

One of the key points Allen discussed at the Steel Framing Experience 2024, held in Neuquén, Argentina, was the importance of building codes and standards for CFS framing. A critical element of his presentation was the relevance of the International Building Codes, specifically Chapter 22, which addresses the standards for steel framing in construction. These codes help ensure that CFS components meet safety and performance benchmarks necessary for reliable and safe building practices.

Allen also emphasized the role of key CFS standards like S100, S220, and S240. These documents govern the design and installation of structural and nonstructural steel framing components, offering detailed guidelines for engineers and builders to follow. Available through the Cold-Formed Steel Engineers Institute (CFSEI), these standards are crucial in ensuring the integrity and reliability of CFS elements in both residential and commercial projects. Recently, the management of these standards shifted to the SFIA Standards Committee, signaling the SFIA’s growing role in shaping industry practices and aligning CFS framing with modern construction needs.

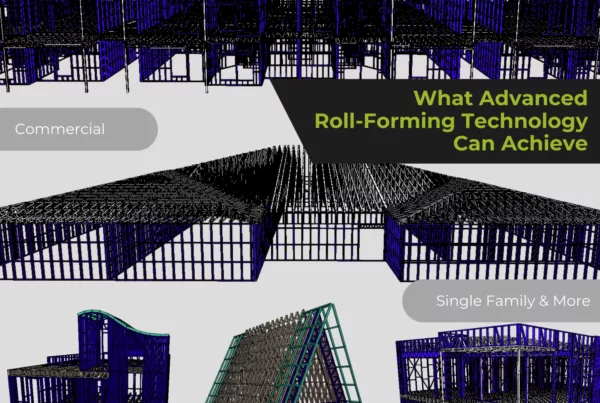

Innovation in Cold-Formed Steel Technology

Allen’s presentation at Steel Frame Experience also showcased the rapid technological advancements driving the CFS industry. One such innovation is the development of built-up floor trusses, which use a single coil for both web and chord members, with additional fasteners to enhance shear strength. This innovation improves load-bearing capacity, especially in areas with high shear loads, making CFS framing more adaptable to complex structural demands. Allen shared a case study from Nigeria, where retrofitting was required for trusses in buildings with non-bearing interior walls that were unintentionally bearing loads. This real-world example illustrates the importance of precise truss design and load distribution in steel framing systems.

Another breakthrough discussed was the incorporation of Exterior Insulation and Finish Systems (EIFS) in cold-formed steel framing. EIFS allows for cold-formed steel panels to be finished with a variety of textures and colors, providing both enhanced aesthetic appeal and improved insulation for buildings. This technology has seen increasing popularity in the United States and demonstrates how CFS can be customized to meet both functional and aesthetic needs. The ability to integrate features like guardrails during shop fabrication adds further versatility, making CFS a flexible solution for modern construction.

CFS and Construction in North America: A Case for Sustainability and Efficiency

A significant theme of Allen’s presentation was the sustainability of CFS framing. As the most recycled material globally, steel is an environmentally responsible choice for modern construction. Allen pointed out that North America recycles more steel annually than paper, aluminum, plastic, and glass combined. The 100% recyclability of CFS ensures that it can be reused without losing its structural integrity, reducing the need for new raw materials and contributing to a more sustainable construction process.

Durability is another key benefit of CFS. Buildings constructed with CFS are designed to last longer, reducing the frequency of repairs and replacements. This not only minimizes maintenance costs but also reduces the environmental footprint associated with rebuilding and repairs, which are common with other construction materials.

A prime example of the efficiency and scalability of CFS framing is the Poly Canyon Village project at California Polytechnic State University in San Luis Obispo. This project, which included nine buildings, is the largest CFS load-bearing framing project in California. Completed in just 14 months—six months ahead of the original 20-month schedule—this development showcases the time-saving potential of CFS in large-scale construction projects. The project featured 11,000 load-bearing wall panels and was constructed on slab foundations. The rapid construction timeline highlights CFS’s ability to meet demanding schedules while delivering a durable, high-quality finished product.

Through his presentation, Allen underscored that CFS is not only a practical and efficient solution for construction, but also a vital tool for achieving sustainability in modern building practices. As construction demands grow and sustainability becomes increasingly important, CFS will continue to play a crucial role in the future of North American construction, offering both environmental and practical benefits.

A Bright Future for Cold-Formed Steel Construction

Don Allen’s insights at the Steel Frame Experience 2024 illustrated the growing importance of cold-formed steel in modern construction. From its adherence to critical building codes and standards to its role in fostering innovation and sustainability, CFS remains an essential material in the construction industry. As new technologies and advancements continue to shape the future of CFS, the material is poised to meet the increasing demands of both residential and commercial projects. Allen’s presentation reinforced that CFS offers a sustainable, efficient, and durable solution that is well-suited to the evolving needs of today’s construction landscape.

As the construction industry moves toward more sustainable and efficient building practices, the Scottsdale Construction Systems offers excellent solutions. Scottsdale utilizes the latest advancements in CFS technology, ensuring faster construction, lower environmental impact, and higher durability for residential, commercial and industrial buildings. With a focus on efficiency, scalability, and innovation, Scottsdale is paving the way for the future of steel framing. By leveraging the benefits of CFS—sustainability, recyclability, and enhanced performance—the Scottsdale Construction Systems delivers high-quality, cost-effective solutions tailored to meet the demands of today’s rapidly evolving construction market. Whether you’re building a multi-story cold-formed steel commercial space or a steel frame house, Scottsdale Construction Systems can help you build faster, smarter, and more sustainably.

Call us at 1 (888) 406-2080, or email us at rollformers@scottsdalesteelframes.info for more information on our cold-formed steel framing solutions.