The Cold-Formed Steel Engineers Institute Expo 2025 (CFSEI Expo), is one of the premier events in the field of cold-formed steel (CFS), bringing together engineers, architects, manufacturers, contractors, and other industry professionals to explore the latest developments, technologies, and best practices in cold-formed steel design, roll forming, manufacturing and construction. Set to take place from May 19–21, 2025, this three-day expo will feature a range of educational sessions, hands-on workshops, and ample networking opportunities, making it a vital event for anyone involved in the CFS industry.

At the 2025 CFSEI Expo, attendees will have the chance to gain Continuing Education Credits (CECs) while participating in an array of technical and practical presentations. These sessions will cover a broad spectrum of topics, such as the latest innovations in cold-formed steel design, CFS seismic design, advancements in mixed reality for construction, the role of artificial intelligence in structural engineering, and much more. Whether it’s about designing cold-formed steel members with improved performance or addressing industry challenges with cutting-edge technology, the CFSEI Expo will serve as an invaluable resource for professionals eager to stay at the forefront of our industry.

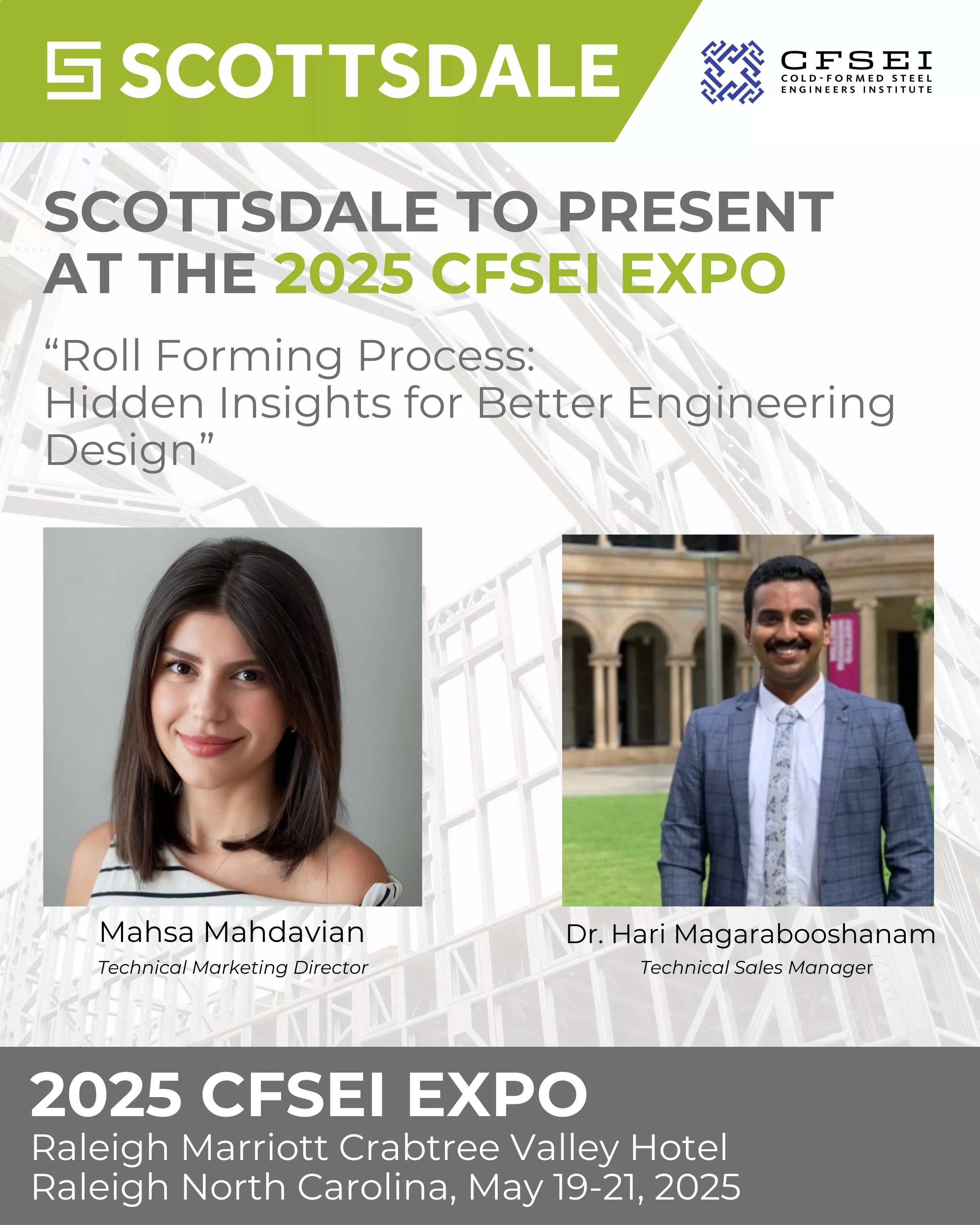

Scottsdale Construction Systems at 2025 CFSEI Expo

Scottsdale Construction Systems will be at CFSEI Expo as a Gold Sponsor of the event and will also be showcasing their innovative solutions as an exhibitor. Hari Magarabooshanam and Mahsa Mahdavian from Scottsdale Construction System will be presenting on Tuesday, May 20th on “Roll Forming Process: Hidden Insights for Better Engineering Design“. This session will explore the roll forming process, a critical component in cold-formed steel manufacturing, and how a deeper understanding of this process can lead to more efficient and effective engineering designs.

The roll forming process is essential for creating cold-formed steel members, but many engineers may not fully appreciate how subtle variations in the process can affect the material’s properties and overall performance. Mahsa and Hari will provide an in-depth look at the hidden aspects of roll forming that can influence the strength, flexibility, and durability of the final product. By understanding these intricacies, engineers can design better structural systems that maximize material performance and reduce waste.

The session will highlight practical insights that can be applied in the real world, helping engineers optimize their designs and improve the efficiency of their projects. Attendees can expect to gain actionable knowledge that will directly benefit their work in cold-formed steel framing, whether they’re involved in design, fabrication, or construction.

Key learning objectives of “Roll Forming Process: Hidden Insights for Better Engineering Design” include:

1. Understand the Role of Cold-Formed Steel in Modern Construction: Recognize the factors driving the popularity of light gauge steel construction systems and identify the challenges engineers face in designing and specifying cold-formed steel components like trusses, panels, and connections.

2. Evaluate the Impact of Roll Forming Manufacturer Operations: Learn the advanced operations used by roll-forming manufacturers (such as coping, swaging, and notching) and how these operations affect the structural performance and procurement feasibility of cold-formed steel sections.

3. Apply Best Practices in Cold-Formed Steel Section Selection: Understand the implications of selecting cold-formed steel sections for structural design, particularly considering the manufacturer’s profile, stiffeners, ribs, and their effect on overall design performance.

4. Assess the Connection Design for Cold-Formed Steel Members: Examine the role of connection design in cold-formed steel structures, focusing on common operations that affect connections (such as pre-punch holes, cuts, and other smart operations), and their importance in maintaining structural integrity.

5. Integrate Load Flow Analysis in Trusses and Wall Panels: Analyze load flow paths within wall panels and trusses, with an emphasis on eccentric truss connections and end-bearing connections, and how they influence the overall strength and stability of cold-formed steel systems.

Overall, the 2025 CFSEI Expo is an essential event for anyone in the cold-formed steel industry, providing valuable learning and networking opportunities. The presentation by Mahsa Mahdavian and Hari Magarabooshanam will offer a unique perspective on the roll forming process and its implications for better engineering design. Learn more about roll forming equipment and process by contacting us at sales@scottsdalesteelframes.com or calling us at +1 (888) 406-2080.