Cold-formed steel (CFS) has become a critical material in modern construction, particularly in mid-rise and modular space. Renowned for its strength, sustainability, and versatility, cold-formed steel has found its place in the building industry. One of the leading voices, Don Allen, P.E., S.E., LEEP AP, Executive Director of the Steel Framing Industry Association (SFIA), has actively contributed to the industry since 1990. In this 60-minute interview, Don Allen shares his experience, and the evolution of cold-formed steel, steel framing, and roll-forming.

Don Allen’s Journey into the Steel Industry

Don’s career in the cold-formed steel industry began after transitioning from the Air Force, working on planes, into construction by joining a steel framing company, where he became fascinated with the unique properties of cold-formed steel. Early in his career, he faced the challenge of performing complex iterative calculations for steel framing before software tools became widely available.

Over time, Don realized the importance of customer service and fieldwork. He emphasizes how crucial it is to engage with contractors on job sites to understand the practical applications of cold-formed steel framing. One of his favorite aspects of the job is product development, which he likens to “cold-formed steel origami,” exploring how materials behave under load and adapting designs to meet real-world challenges. Watch Don Allen’s full interview with Scottsdale Construction Systems below.

Cold-Formed Steel Industry Trends & Evolution

In the past decade, the cold-formed steel industry has undergone significant transformations, driven largely by technological advancements. The rise of sophisticated software tools has streamlined the design process, enabling individuals with limited knowledge of design to conduct analyses and determine specifications. While this has increased accessibility, Don highlights that incorrect assumptions or parameters can lead to design errors, underscoring the importance of continuous education.

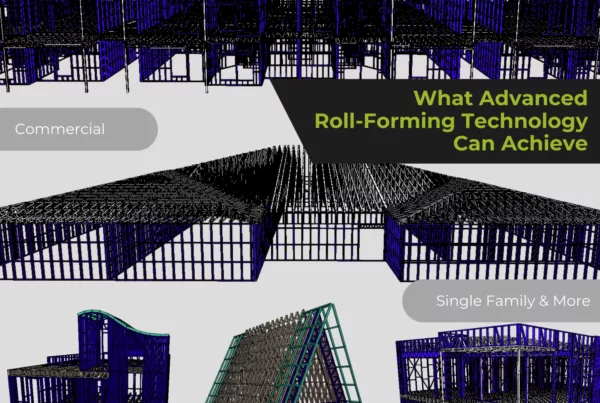

Another major development has been the response to labor shortages, which has prompted innovations in tools and processes. Labor-saving technology, prefabricated design systems, and the integration of computer-aided manufacturing have all improved production efficiency. Don alludes to Scottsdale Construction Systems as an innovator in roll-forming technology stating, “There is a lot of innovation in our industry. With companies like yours, these roll-forming machines that are tied with computer-aided manufacturing allow someone to design and then immediately produce the products and produce the panels.” All of this creates the opportunity for cold-formed steel to be increasingly used in mid-rise floor systems, particularly in urban areas where the demand for high-rise buildings continues to rise.

Don also compares the U.S. cold-formed steel framing market with global trends. In countries like the U.S., tall CFS buildings, including 17-story structures in cities like New York, are common. In contrast, many other countries are more conservative, often limiting buildings to three stories due to concerns about material capabilities and advanced machinery. However, with cold-formed steel’s proven potential, more international markets are considering it for modular construction, particularly in fire-prone regions like California.

Sustainability & Environmental Impact of Cold-Formed Steel

Sustainability is becoming a core focus in the cold-formed steel industry. Over the last 10 to 15 years, the sector has introduced thinner, lighter studs that maintain strength while reducing embodied carbon. These innovations help architects minimize the carbon footprint of steel framing, making it an increasingly attractive option for environmentally conscious builders.

A key factor in the industry’s sustainability push has been the shift towards electric arc furnaces (EAF), which use over 90% recycled steel. This significantly lowers the environmental impact of steel production. Furthermore, advancements such as green hydrogen in steelmaking are helping to further reduce emissions.

Cold-formed steel’s dimensional stability also plays a role in improving energy efficiency. By preventing thermal bridging and maintaining a sealed building envelope, cold-formed steel contributes to better insulation and reduced energy costs. Don emphasizes the progress that has been made in addition to the developments to improve transparency and comprehensive environmental product declarations (EPDs) to help architects make informed decisions.

Opportunities & Future of Cold-Formed Steel

Looking to the future, Don is optimistic about the role of emerging technologies like robotics, modular construction, and even exoskeletons. Automation in manufacturing and the transportation of modular units is expected to reduce waste and improve efficiency. Innovations in container-based manufacturing operations, which allow for on-site fabrication, will further minimize environmental impact.

The rise of contractor manufacturers, who produce materials on-demand for specific projects, aligns with the industry’s push for more flexibility and faster permitting processes, ultimately reducing construction timeframes and budgets.

Don also notes the importance of attracting new talent to the construction industry. He encourages the new generation to consider careers in cold-formed steel, highlighting the potential for creativity and high-tech innovation. With advances in technology and reduction in regulations, the future of cold-formed steel offers exciting opportunities for growth and innovation.

The cold-formed steel industry has evolved significantly in the last few decades, driven by advancements in technology, sustainability, and efficient manufacturing practices. As the demand for more sustainable building solutions grows, CFS is poised to play a key role in shaping the future of construction. Don Allen’s extensive experience offers valuable insights into industry’s evolution and its potential for continued innovation.

Scottsdale Construction Systems’ Role in Advancing Roll-Forming

The cold-formed steel industry continues to evolve, driven by advancements in technology, sustainability, and manufacturing efficiency. As the demand for sustainable building solutions grows, emerging technologies like robotics and modular construction are set to revolutionize the way buildings are designed and constructed, increasing efficiency and reducing waste.

Scottsdale Construction Systems is at the forefront of this evolution, offering a comprehensive range of roll-forming machines, cutting-edge software, and unparalleled support services to meet the industry’s needs. We are committed to providing industry-leading solutions that drive the future of cold-formed steel framing. Learn more about Scottsdale’s ecosystem and explore our roll-forming technology.